Fusion 360 Injection Mold Design: Template for Tool Design

Price: $49

Introduction to Mold Design

Mold design stands at the heart of successful injection molding, shaping the quality, cost, and manufacturability of every plastic part produced. With Fusion 360, designers and engineers gain access to a comprehensive suite of CAD tools tailored for creating and refining mold designs. Whether you’re starting with a template or building a custom solution from scratch, Fusion 360’s intuitive interface and powerful features make it easy to create molds that meet the highest standards.

A key advantage of using Fusion 360 for mold design is its ability to handle complex elements such as parting lines, cores, and cavities with precision.

Fusion 360 also streamlines collaboration, allowing teams to connect, share data, and iterate on designs in real time. Engineers and designers can quickly adjust settings, analyze draft and surface finish, and ensure that every part meets the required specifications. The platform’s robust functionality supports everything from initial sketches to final analysis, making it a valuable tool for companies aiming to accelerate product development and improve manufacturing outcomes.

For those new to mold design or looking to expand their skills, Fusion 360 offers a wealth of resources—including tutorials, videos, and user forums—making it easy to learn best practices and stay up to date with the latest features. By leveraging Fusion 360’s advanced CAD capabilities and managing Fusion 360 models and Fusion 360 files efficiently, designers can create high-quality molds, reduce lead times, and deliver superior products to market.

Whether you’re an experienced engineer or just starting your journey in injection molding, Fusion 360 provides the tools, flexibility, and support you need to bring your mold designs to life and drive manufacturing success.

Optimize Your Injection Mold Design Process

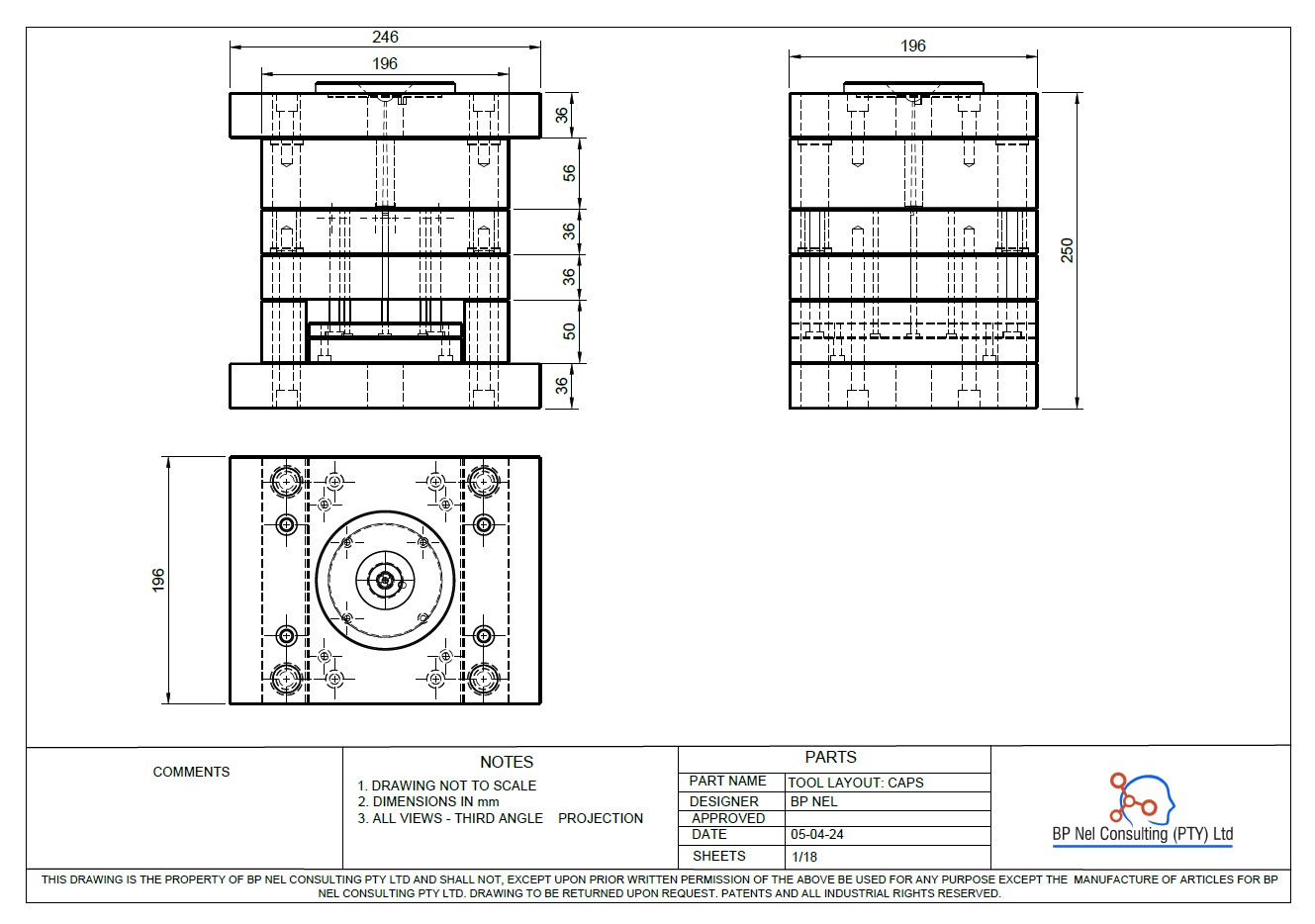

At BP Nel Consulting, we offer a powerful Fusion 360 template specifically designed for injection mold tool design. The job of an engineer or analyst in this process involves evaluating manufacturing feasibility and providing feedback on plastic part production to ensure optimal results. This template is available in the native Fusion360 format and is meticulously crafted to enhance your design efficiency and precision.

Our template supports the design of molds for plastic injection processes, enabling you to create complex parts and bodies with ease. Whether you are working on intricate product geometries or optimizing parts for manufacturability, this tool streamlines the workflow for injection molding projects.

Key Features:

1. Parametric Design:

Our mold base template is designed with robust parameters that drive the entire design. When you adjust any parameter, all relevant dimensions and features automatically update. This dynamic adaptability ensures consistency and accuracy across your project.

2. Comprehensive 2D Drawings:

Included with the template are detailed 2D drawings for each individual component of the mold. These drawings update in real-time with any changes made to the 3D model, providing you with up-to-date documentation throughout the design process.

3. Time-Saving Solution:

Ideal for injection mold tool designers and tool makers, this template significantly reduces the time required for modeling. By leveraging our pre-designed mold base, you can save weeks of modeling time and focus on refining other critical aspects of your project.

Why Choose Our Fusion360 Mold Base Template?

Efficiency and Precision:

Our template is engineered to streamline the design process, allowing for quick modifications and updates. This precision-driven approach minimizes errors and ensures that your mold designs meet the highest standards.

Native Fusion360 Format:

Available in the native Fusion360 format, our template integrates seamlessly into your existing workflow. This compatibility ensures a smooth transition and immediate usability.

Comprehensive Documentation:

With up-to-date 2D drawings included for each component, you have all the documentation you need at your fingertips. This feature supports both the design and manufacturing stages, providing clarity and detail at every step.

Ideal for Professionals:

Whether you are an experienced mold tool designer or a tool maker, our Fusion360 template offers the flexibility and control you need to create high-quality injection molds efficiently.

Boost Your Productivity

Upgrade your injection mold design process with our Fusion360 template. Designed to save you time and enhance your workflow, this template is an invaluable resource for professionals seeking to optimize their design and manufacturing processes.

Check out our additional resources and tutorials on Fusion 360 injection mold design to deepen your expertise. Follow our step-by-step guides from BP Nel Consulting to ensure you get the most out of your template. If you have any questions about the template or the injection mold design process, don't hesitate to reach out. Watch our demonstration videos to see the template in action and streamline your workflow.

Get Started Today!